Pressed Brick

Elegant Yet Durable

Some brick buildings standout for the beauty of their brick. This is particularly true for those constructed of pressed brick, an older brick, popular from the 1860s through the early 20th Century. It has a smooth surface, even sharp edges, and very thin mortar joints. (Figure 1). The brick was made of very fine, dry clay pressed into molds under great pressure by hydraulic or screw presses and then fired in a kiln almost immediately without an intermediate drying phase. The use of dry clay ensured minimal shrinkage. Pressed brick is denser and harder than common brick, and has a higher absorption rate. Despite its high absorption, pressed brick is very durable.

Figure 1: Pressed brick with thin mortar joints.

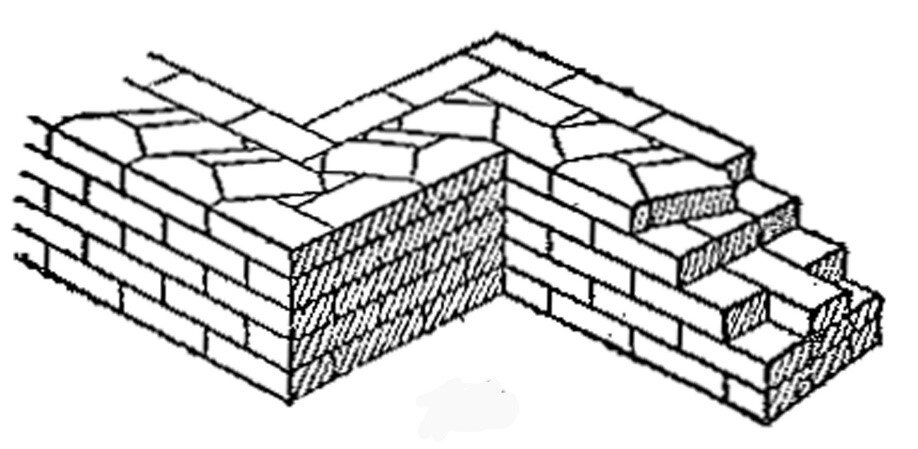

Pressed brick was more expensive than common brick so consequently installed as face brick over a common brick backup wall. These brick are almost always laid in a stretcher bond with vertical joints staggered by half a brick. The most common method for tying the face brick to the backup wall was the use of clipped brick and blind headers (Figure 2). A blind header is header brick, laid at a sixty-degree angle, set behind the stretchers to the load bearing masonry behind. The back corners of the face brick are clipped to receive the edges of the headers. The bricks were laid in a lime mortar with very fine aggregate to achieve the thin joints. Unfortunately, this brick bond is not strong. It is probable metal brick wall ties, first commercially manufactured by the 1890s, came into common use because of poorly performing clipped brick bonds.

Figure 2: Illustration of wall laid in a stretcher bond. Blind headers are created by laying a header brick on an angle to tie the face of the wall to the back-up brick behind.

We found pressed brick at a former school building in New York City with a stretcher bond and blind headers with clipped face brick (Figure 3). In this instance the joints were well filled but they often are not. Repointing the thin mortar joints in these bricks is difficult and requires a lot of skill. All too often, contractors overcut the joints when they try to rake out the mortar.

Figure 3: Clipped brick bond with well-filled mortar joints.

Over time, water entering pressed brick walls washes out the lime mortar and it is not uncommon for these walls to start bulging. Of course, pressed brick walls can also bulge for other reasons. At a recent townhouse project the façade wall was found to be one pressed brick wythe thick without a backup wall. The poor contractor working on the townhouse’s interior was given pause to find he could push the wall out with his finger. Needless to say, major repairs were required but the pressed brick was kept as the face brick.